YOUR CART

- No products in the cart.

Subtotal:

$0.00

BEST SELLING PRODUCTS

$249.99 + HST

$124.99 + HST

$1,299.99 + HST

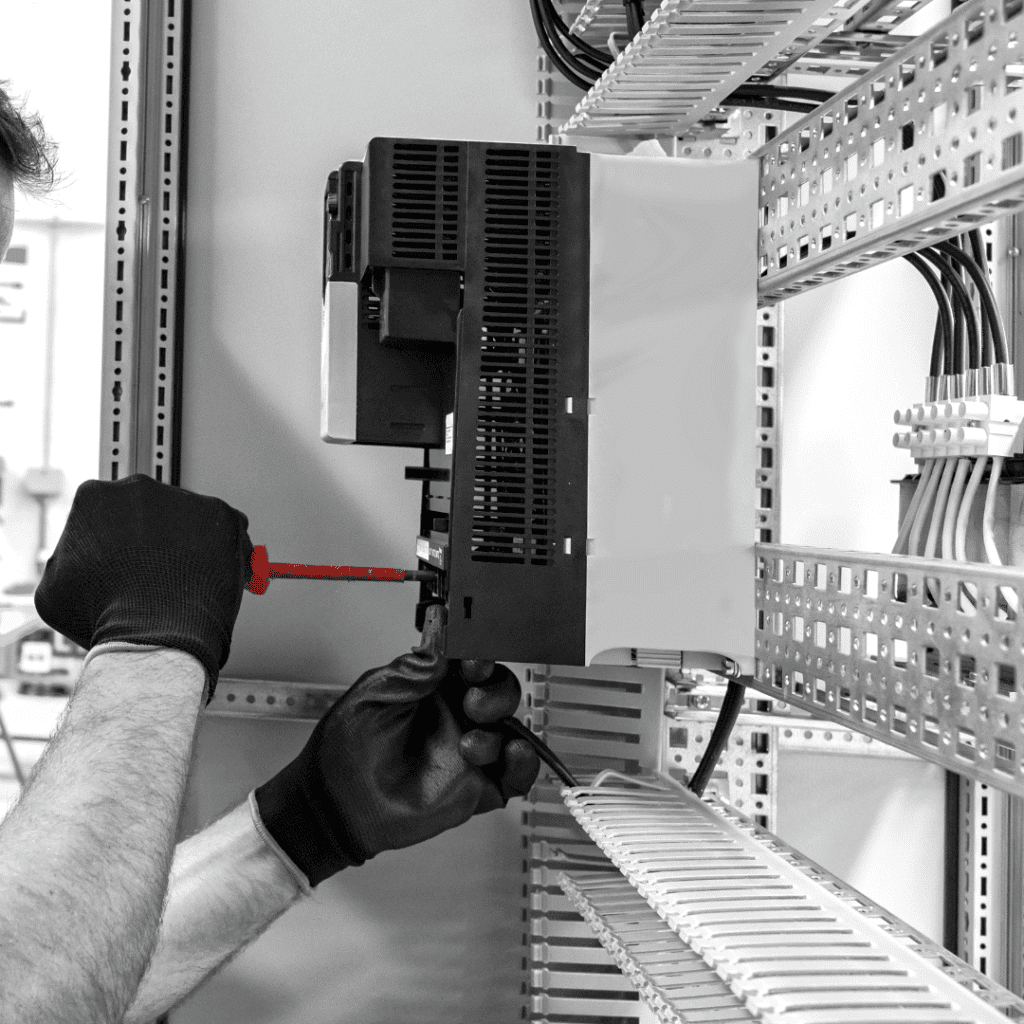

I've spent more than ten years managing, troubleshooting, and installing ABB Drive models ACS550-600-800-880s in the industrial sector, so I know a thing or two about how to keep production going!

Allow me to bring that success to your manufacturing process and assist you in maximizing productivity.

I've spent a lot of time successfully integrating various pieces of mechanical and software equipment using Siemens integration sinamics g120x drives in the industrial sector.

I can offer the expertise and knowledge to work with your team and keep your facility running with the least amount of downtime thanks to my experience working with Benshaw to provide maintenance on medium voltage soft starters and across-the-line starters.

There is, of course, Rockwell Automation and Allen Bradley hardware. Although Allen Bradley PLCs have been around for a while, like any PLC devices, the technology is outdated when compared to an ABB PLC.

A Variable Frequency Drive (VFD), also known as a Variable Speed Drive (VSD) or Adjustable Frequency Drive (AFD), is a type of motor controller that regulates the speed and torque of an electric motor by varying the frequency and voltage of the electrical power supplied to the motor.

VFDs are commonly used in various applications, including HVAC systems, pumps, fans, conveyors, machine tools, and industrial automation processes, where precise control over motor speed and torque is required.

Energy savings: By controlling the speed of the motor according to the load requirements, VFDs can reduce energy consumption compared to fixed-speed motors running at full speed.

Improved process control: VFDs provide precise control over motor speed, allowing for better control of industrial processes and equipment.

Soft-start and soft-stop: VFDs can gradually ramp up the speed of the motor during startup and ramp it down during shutdown, reducing mechanical stress on the motor and connected equipment.

Reduced wear and tear: By minimizing abrupt changes in speed and torque, VFDs can extend the lifespan of motors and mechanical components.

Would you like to receive a monthly email with the newest trends, tips, reviews, and discounts? Yes? For a monthly update, sign up below.

Do you have any questions about a project or would you like to work together to build a working commitment? To get started, just fill out the form here.